Last June 4th, German minister of Economy (Peter Altmaier) has announced a massive 9B€ investment in the "Renewable Hydrogen (RH2)" value chain. He wants Germany to become the world leader in the green H2 business.

How to explain this move? is it realistic? and if yes for what use cases?

Let's try to understand the driving forces, benefits and costs.

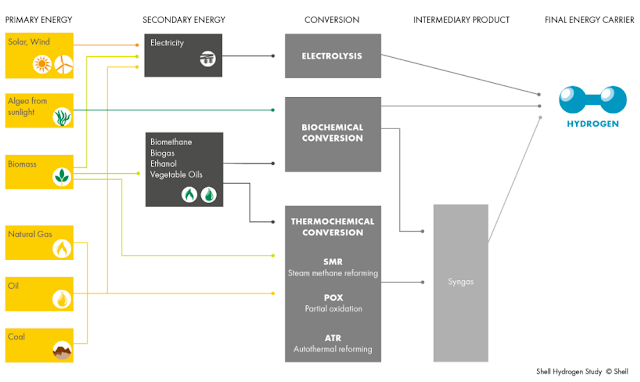

Di-Hydrogen (H2) is a gaz and does rarely exist in its pure form. It is therefore obtained from its compound through carbonized method (70% of today produced hydrogen ), biochemical conversion and through electrolysis of H2O (source Hydrogen Europe platform):

It is mostly used in industry (50 % in Refineries, 45 %for Ammonia-based fertilizers production, and 5% for other needs such as electricity generation) - Source IEA-

Di-Hydrogen carry the highest energy content in weight (compare to common fuels) but the lowest in volume. To concentrate the energy stored per volume unit, several methods can be used. The most common one is to compress the gas (up to 700 bars). The compressed gaz (or liquid) obtained can be stored over a long period, can be moved where it is needed for chemical industries or can by used to produce electricity through a fuel cell (combined with O2, the reaction produce energy and H2O).

The later use case is called "power to H2 to power" cycle.

Several advantages and disadvantages can be pointed out:

The total power to power yield is very poor: from electricity to electrolysis, to compressor to fuel cell, we obtain barely 25-30 % of the electricity injected at the entrance. This is to compare with 70 % for Batteries.

- The high pressurized storage technology (up to 700 bars) makes it expensive for small capacities (between to 1000-2000$/tank depending on volume produced - source DOE-).

- last but not least, safety hazards exists in H2 chain in case of leakage: H2 gaz react easily with O2 in air and and form an explosive mixture.

On the benefits side:

- the Hydrogen production (electrolysis plants) can be built near green electricity production sites (avoiding loss and costs of transportation and taking advantage of green energy production surplus)

- Storage costs benefits from the economy of scale.

- Transportation of compressed H2 and Storage over a large amount of time is quite simple.

- unbeatable energy/weight compare to other sources of energy: a typical volume of 60-80 Kg H2 is needed for a truck delivering 300kW power over a 400 miles (vs 7Tons of batteries)

- the filling time of a

To summarize and taking into account "total cost of ownership" analysis, Hydrogen production and storage makes sense in the following cases -source Hydrogen Europe platform-:

Batteries, supercapacitors or flywheels makes more sense for small storage capacity and instant needs. these solutions are attractive as buffers to smooth out longer latency production systems. Batteries are good for regenerative brake systems for exemple and light vehicles.

The hydrogen production chain is more attractive for large and long time energy storage.

Germany has today an installed base of 60 GW of wind turbines + 50 GW of solar panels for electricity production. The government has stepped in to address production/consumption unbalance: its ambition is to build 3 to 5 GW electrolysis power plants (to produce Hydrogen) in the coming years complemented by extra 5GW by 2030. It aims also to develop Renewable H2 transportation network to distribute H2 throughout the country. The goal is first to de-carbonize industries.

Renewable H2 can also make sense for future mobility. First for large trucks (Germany plans to build H2 fuel stations all over their motorways). Several truck maker (such as Nicola motor) are already proposing H2 fueled truck models. Second for smaller and lighter vehicles like cars. While WV doesn't believe in fuel cells solutions for cars for the next decade, BMW head of R&D has recently announced that they maintain versatile power trains to accommodate various fuel solutions. A lot of research is ongoing to store H2 on a solid substrat with the aim to reduce the total cost of H2 solution and compete with battery storage for E-vehicles (see Hydrogen Europe Storage page for more information).

To complete the mobility chapter, some companies are also developing H2 fueled trains (like the coradia iLint from Alstom) H2 fueled airplanes (like zero-avia, or HES) or H2 fueled Ebikes (Pragma industries)

Worth to mention that H2 can also be used in the natural gaz network for building heating.

Is therefore Renewable H2 the solution to address climate change? Certainly not. For short term it can help to decarbonize some industries. However refineries will also need to be decommissioned at some point. Intensive agricultural model based on large ammonia fertilizers production plants will also need to be converted to more small scale agro-ecological model.

We also believe that it can play a role to balance electricity surplus and address mobility of the future: Mobility model based on EVs running on batteries, as heavily promoted by VW, remains fragile as it rely on tens of limited compounds (cobalt, nickel,...), in hands of few companies in the world and comes up with high environmental production/decommissioning cost.

To make it happen, we still need strong incentives from governments (legal framework and subsidies): In 2018, "Renewable H2" cost of production (3 to 7 $/kg) were twice higher than "Brown H2" cost of production (2 to 3 $/kg) - source IAE-.

Comments

Post a Comment